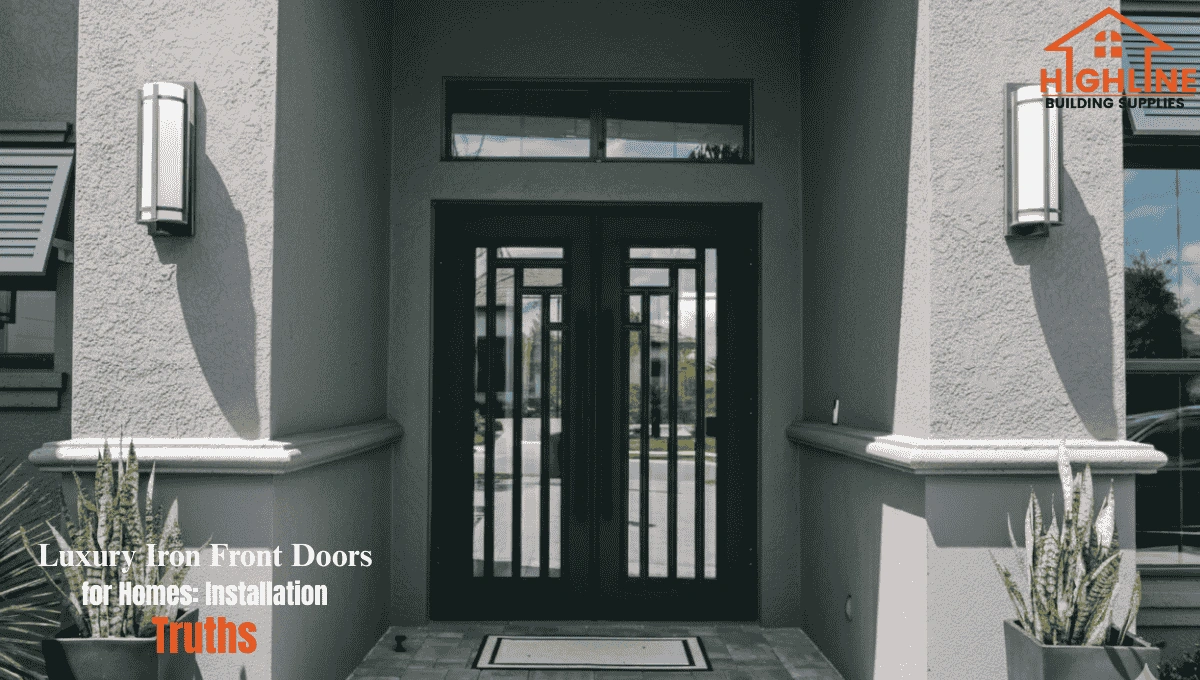

Upgrading to luxury iron front doors for homes is one of the most dramatic changes you can make to a property’s exterior. But what many homeowners don’t realize is that installation—not just design or price determines whether that investment performs beautifully for decades or becomes a constant headache.

As someone who has worked hands-on with entry systems, framing adjustments, and exterior renovations, I can confidently say this: iron doors are not just another door swap. They require planning, structural awareness, and proper sealing techniques that differ significantly from standard wood or fiberglass units.

This guide walks you through the real installation truths what works, what fails, and what homeowners often misunderstand.

Why Installation Matters More Than the Door Itself

A premium wrought iron door is engineered to last. Heavy-gauge steel frames, reinforced hinges, insulated glass, and weather-sealed cores are built for durability and security.

But improper installation can cause:

- Air leaks and poor insulation

- Water infiltration

- Door sagging over time

- Misalignment that damages locking mechanisms

- Premature rust around seams

In other words, even the best door can fail if the opening isn’t prepared correctly.

At Highline Supplies, we often see homeowners focused on aesthetics—arched tops, decorative scrollwork, or statement pieces like a 3/4 Lite Arched Wrought Iron Double Door—but overlooking framing and structural requirements. That’s where most problems begin.

Understanding the Weight and Structural Demands

Luxury iron doors are significantly heavier than wood or fiberglass models.

Typical Weight Comparison

- Standard fiberglass entry door: 80–120 lbs

- Solid wood door: 100–150 lbs

- Iron single door: 250–400+ lbs

- Iron double door system: 500–800+ lbs

That weight changes everything.

What This Means for Installation

- Framing must be square and reinforced

- Subfloor must be level and load-capable

- Hinges must be properly aligned and anchored

- Anchoring hardware must match structural material (wood framing vs. masonry)

Skipping reinforcement often leads to sagging within the first few years.

Pre-Installation Planning: The Step Most People Rush

Before installation even begins, consider these key factors:

- Rough Opening Accuracy

Iron doors have tighter tolerances than many other materials. A rough opening that’s even slightly out of square can lead to sealing and locking issues.

Professional installers check:

- Diagonal measurements

- Plumb alignment

- Level threshold surface

Even a 1/8-inch variation can create long-term problems.

- Threshold and Drainage

Iron doors must be protected from standing water.

Best practice includes:

- Sloped exterior surfaces

- Proper flashing

- Waterproof membrane under threshold

- Sealant rated for exterior metal

Water intrusion is the most common cause of rust at the base of entry systems.

- Climate Considerations

Iron expands and contracts with temperature changes.

In hot climates:

- Thermal expansion affects seals

- Dark finishes absorb heat

In cold climates:

- Condensation control becomes critical

- Insulated glass options matter more

This is why choosing between traditional designs and modern exterior doors isn’t just stylistic—it affects performance based on region.

Single vs. Double Iron Door Installation Truths

Double-door systems, such as the 3/4 lite Texas Star Double Wrought Iron Door, add another layer of complexity.

Common Double-Door Challenges

- Active and passive leaf alignment

- Flush bolt calibration

- Center meeting seam sealing

- Consistent latch pressure

If the center seam isn’t sealed properly, drafts and water infiltration can occur—even if the outer perimeter is perfect.

Sealing and Weatherproofing: Where Most Failures Happen

Iron itself doesn’t “fail” easily. Weather sealing does.

Best Practices

- Use high-quality compression weather stripping

- Ensure glass panels are insulated and sealed

- Apply rust-resistant primer on exposed metal cuts

- Seal all anchor penetrations

Cheap sealants shrink over time. When that happens, moisture enters—especially around screw holes.

From hands-on experience, I recommend checking seal integrity annually during seasonal maintenance.

Rust: What’s Normal vs. What’s Preventable

Many homeowners assume iron doors will rust quickly. That’s not true—if they’re installed and maintained correctly.

What Causes Premature Rust

- Scratched powder coating left untreated

- Poor drainage under threshold

- Unsealed anchor penetrations

- Coastal salt exposure without protective coatings

What Works

- Touch-up kits for surface scratches

- Annual inspection

- Clear protective wax application in humid regions

Rust typically starts at the bottom edge where water pools. Proper flashing eliminates most of that risk.

Buying Online vs. In-Store: Installation Implications

More homeowners now buy exterior doors online, which can offer broader style options and pricing transparency.

However, online purchasing requires:

- Precise measurements

- Clear understanding of rough opening specs

- Professional installation planning before delivery

A mismeasured iron door return can cost significantly due to freight and restocking fees.

When ordering custom systems, always confirm:

- Hinge side

- Swing direction

- Jamb depth

- Threshold type

These details directly affect installation success.

Comparing Iron to Other Building Materials

Choosing iron is often part of a larger exterior renovation. If you’re upgrading entry systems, it’s also wise to evaluate surrounding structural elements.

We’ve covered how critical material selection is in our related guide on building materials. The wrong framing lumber, flashing, or exterior sealant can undermine even the best entry system.

Your door is only as strong as the materials supporting it.

Energy Efficiency: The Reality

Luxury iron doors today are not hollow steel slabs. High-quality systems include:

- Thermal breaks

- Insulated cores

- Double or triple-pane glass

- Compression weather seals

When installed correctly, performance rivals many fiberglass doors.

But poor installation—gaps, misalignment, weak seals—negates these benefits immediately.

Energy efficiency is not just about the product. It’s about the seal.

Common Installation Mistakes (And How to Avoid Them)

- Skipping Structural Reinforcement

Heavy doors require reinforced framing.

- Rushing Sealant Application

Improper curing time leads to long-term leaks.

- Ignoring Flashing

Water always finds a way.

- Improper Shimming

Uneven support causes long-term hinge stress.

- DIY Without Experience

Iron systems are not beginner-level installs.

Expert Tips From the Field

After years of working with premium entry systems, here’s what consistently works:

- Install during mild weather if possible

- Always dry-fit before final anchoring

- Protect the finish during installation

- Confirm swing clearance inside and out

- Use corrosion-resistant fasteners

One overlooked step? Checking the subfloor moisture level. Installing over damp concrete can create long-term corrosion issues.

Real-World Use Cases

Luxury Renovation Project

A homeowner upgrading to a 3/4 Lite Arched Wrought Iron Double Door needed header reinforcement due to span width. Proper structural correction prevented sagging that would have occurred within two years.

Contemporary Build

A client choosing sleek modern exterior doors underestimated sun exposure. Upgrading to insulated low-E glass prevented interior heat gain issues.

Customer Experiences

We assumed replacing our door would be simple. The framing adjustment alone took a full day—but it made all the difference.

— Daniel R., homeowner

Our contractor insisted on re-leveling the threshold before installing our wrought iron door. I’m glad he did—no drafts, even in winter.

— Melissa T., property owner

Buying online was easy, but measuring correctly was critical. Double-checked everything before ordering.

— James L., renovation client

FAQ:

Are iron doors harder to install than wood doors?

Yes. They’re heavier and require more precise framing and sealing.

Do iron doors rust easily?

Not if properly coated and installed with correct drainage.

How long does installation take?

Typically 4–8 hours for a standard replacement. Longer for structural modifications.

Are double doors harder to maintain?

They require periodic alignment checks, but maintenance is manageable.

Can I install one myself?

If you don’t have framing and structural experience, professional installation is strongly recommended.

Final Thoughts: Installation Determines Longevity

Luxury iron entry systems are built to last decades. But longevity depends almost entirely on:

- Structural preparation

- Precision alignment

- Proper sealing

- Ongoing maintenance

When installed correctly, luxury iron front doors for homes provide exceptional durability, security, and architectural impact.

The door itself is only half the story. The installation is the truth most people discover too late.

About the Author

Highline Supplies Editorial Team

Our team works closely with contractors, builders, and renovation professionals across residential projects involving entry systems, framing materials, and exterior upgrades. With hands-on experience evaluating installation challenges and material performance, we focus on practical guidance not marketing hype to help homeowners make informed decisions that hold up in real-world conditions.

Leave a comment